Molded Plastic Accessories

Techno Global (Osaka Prefecture)

Molded Plastic Accessories

Techno Global (Osaka Prefecture)

Accessories designed for texture and form to bring out the beauty of plastic

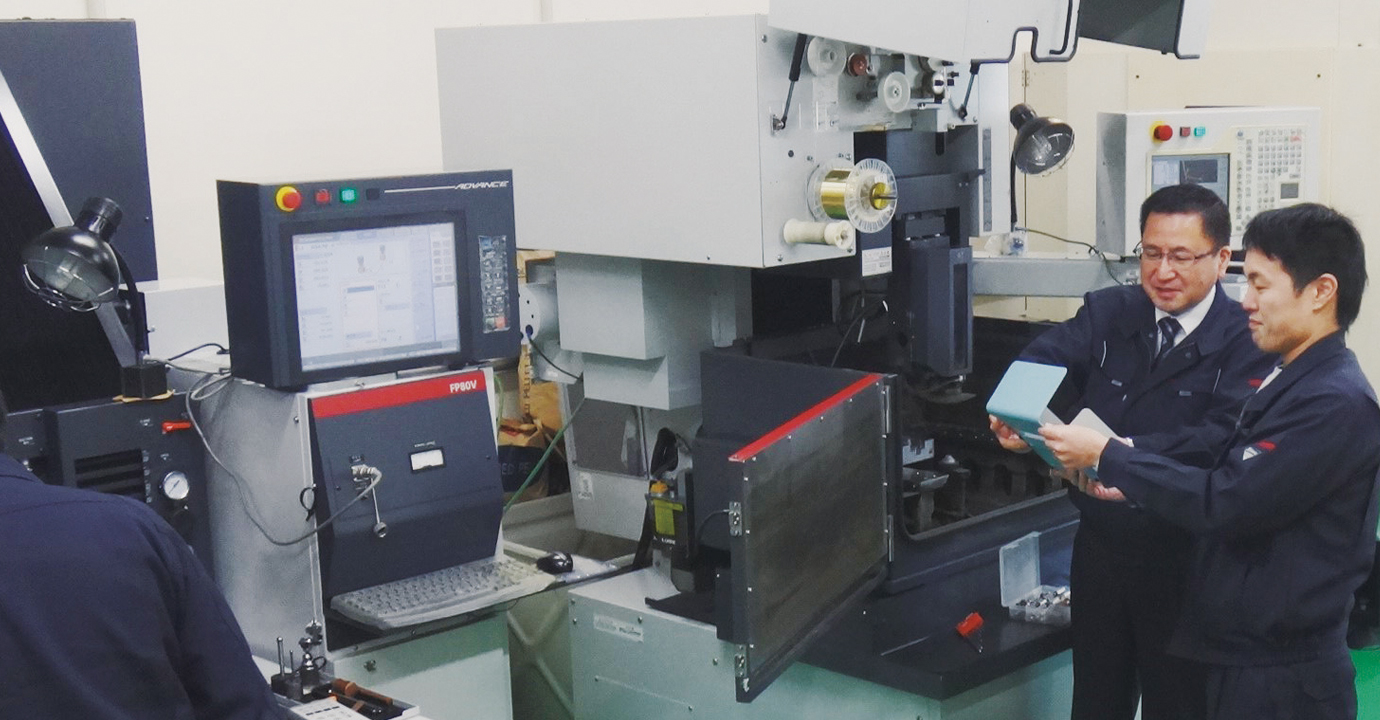

Daily plastic accessories are essential to our daily lives. Metal molding and injection molding technology play a vital role in the manufacturing process. In the past, “mold shops” were used as a primary contractor, with metal mold shops employed as a sub-contractor, resulting in a total division of labor. Doubting the efficiency of this workflow, metal molding expert Hiroyuki Takada founded Techno Global in 2006 to create a once-stop environment to carry out everything from metal molding to injection molding. As time passed, the company grew to launch support for multi-product small lot manufacturing.

“Though I continually thought about creating an in-house brand utilizing the strengths of our flexibility, it was hard to find a way to get the ball rolling,” says Takada. Opportunity struck in 2015 when application to STADI (a creative production enterprise in Yao City) opened up to the public. Through STADI, ambitious SMEs are contracted for production work by product designers, and also work on product development and market entry. Techno Global was paired with Tomoaki Murata at Hers Design Inc. Using the core competency management theory, they spent six months discussing what to make and how to market it, with Murata working in advance to formalize ideas on a plastic molded watch and tissue box. The factory development team used Murata’s design sketches, adding improvements to small details that took usability and production efficiency into account. In the fall of 2016, one year after the company was selected as a candidate in the STADI program, the product was complete. They had developed a product with a beautiful satin-finish matte form, and a chic color scheme. With every last detail taken into account, the product’s simple functional beauty stood out.

“We are learning about previously unknown areas outside of our industry through business meetings with interior accessory buyers. I hope they will come to know about our technology, allowing us to move up to the next level,” says Murata. And so the company continues to embark on yet another challenge.

Techno Global Corp.

1-1-37 Minami-no-cho, Atobe, Yao-shi, Osaka

581-0055

Tel.072-993-7935

http://www.techno-global.co.jp

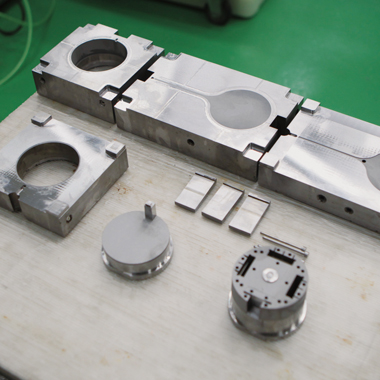

Precision metal molding technology

is the lifeline of manufacturing.

Each part is verified

both visually and by hand.

Skilled hands carefully

and rapidly assemble the product.