Advanced Technologies, AI Robotics, Space Industry

- HOME

- Advanced Technologies, AI Robotics, Space Industry

Kansai Businesses Driven by Enterprising Spirit Lead Charge in Advanced Technologies

The remarkable capabilities of generative artificial intelligence (AI), including its ability to produce natural and context-aware responses, have amazed the world. At the same time, advances in robotics continue to push boundaries at an unprecedented pace. Global tech giants, automakers and companies from other industries are engaged in intense competition to develop cutting-edge technologies such as generative AI, robotics, autonomous driving systems, and space exploration technologies, including rockets.

In Japan, many companies are advancing R&D for cutting-edge technologies. Among them is the Toyota Motor Corp. group, a global leader in vehicle sales, which is actively pursuing innovations in electric vehicles and self-driving technologies. Aiming to bolster the country's technological edge, the Japanese government has announced plans to invest 10 trillion yen by fiscal 2030 in efforts to revitalize the semiconductor and AI industries.

The Kansai region has long been a hub for innovation, driven by a deep enthusiasm for developing cutting-edge technologies. Many attribute the region's economic strength to its "enterprising spirit," which values originality and bold initiatives, and its "tolerance," embracing diversity and learning from setbacks. Notably, Kansai companies were the first in the world to create groundbreaking technologies such as automatic ticket gate systems for public transportation and mobile phones with built-in cameras.

In addition, Kansai is home to numerous universities and research institutes conducting world-class advanced research. The region has become a thriving hub for the development of new technologies and products through strong industry-academia collaboration, with many university-originated startups also emerging. Local governments in Kansai are actively working together to promote cutting-edge industries under the initiative "Deep Tech Valley 'KANSAI.'" Their goal is to transform the region into a global center where people, goods, investment and information come together from all corners of the world.

This section highlights companies and research institutes at the forefront of advanced technologies such as AI and robotics. We invite you to visit these organizations and see their cutting-edge innovations at firsthand.

COMPANY LIST Listings:11

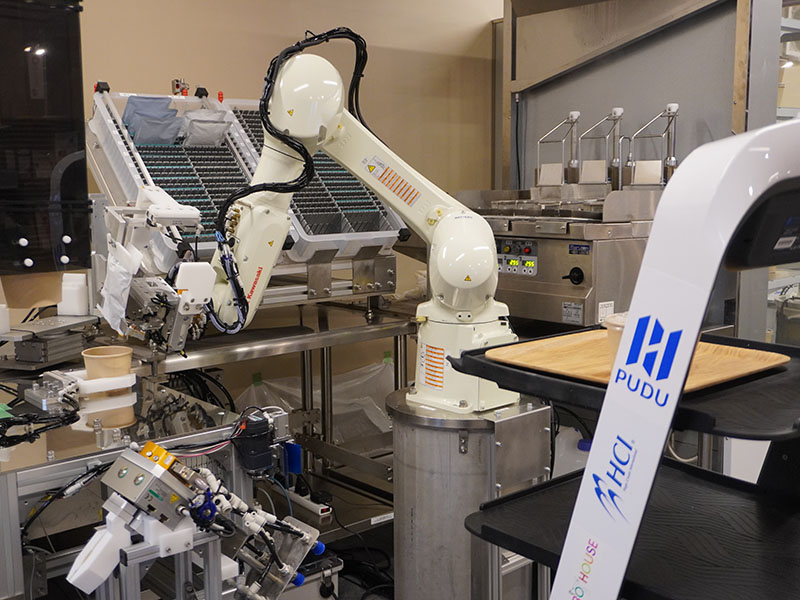

HCI CO., LTD.

Osaka Prefecture

3-14-10 Higashitoyonaka-cho, Izumiotsu,Osaka Prefecture 595-0021

Advanced Technologies, AI Robotics, Space Industry

HCI CO., LTD. Osaka Prefecture https://www.hci-ltd.co.jp/

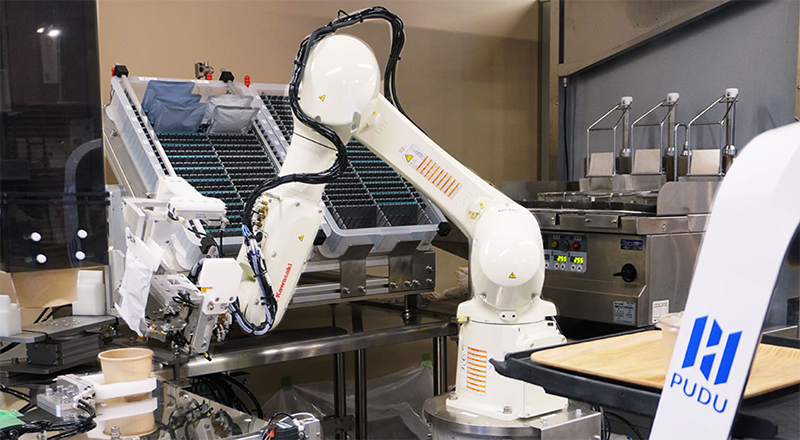

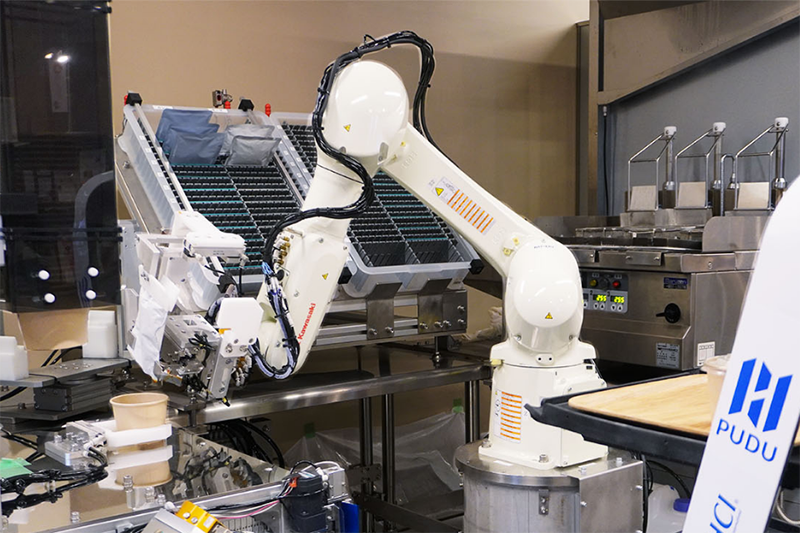

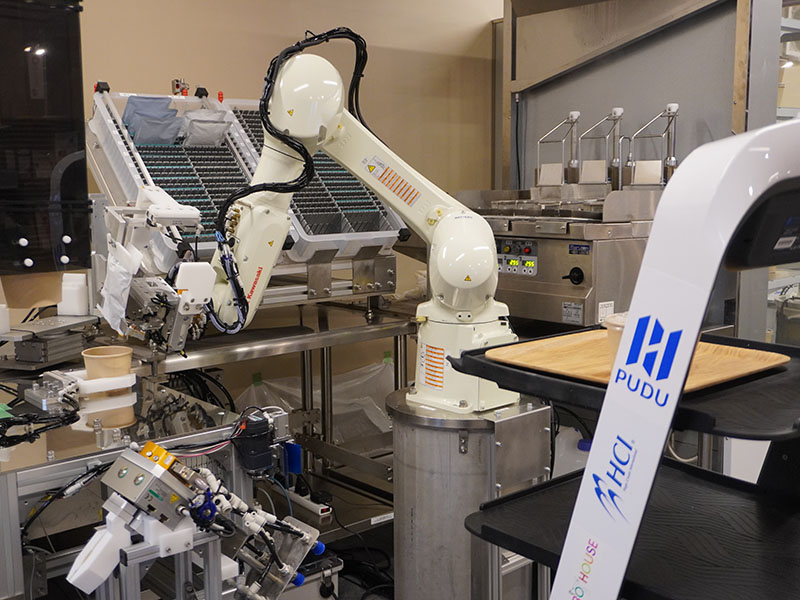

HCI CO., LTD. specializes in robotics and AI technologies,providing robotic systems and AI solutions across various industrial sectors. The company's strength lies in its ability to offer comprehensive one-stop services, from the development of robots and AI robotic systems to delivery and operational support, leveraging advanced technological capabilities honed over many years. Notably,HCI operates a unique employee cafeteria that is fully managed by robots and AI, the first of its kind in the world. This innovative facility not only showcases the company's technological prowess but also makes important contributions to the local community.

Tour Location

About 40 minutes' drive from Kansai International Airport

About 1 hour's drive from Shin-Osaka Station

Availability of Company Tours

Contact Information

Administration Headquarters

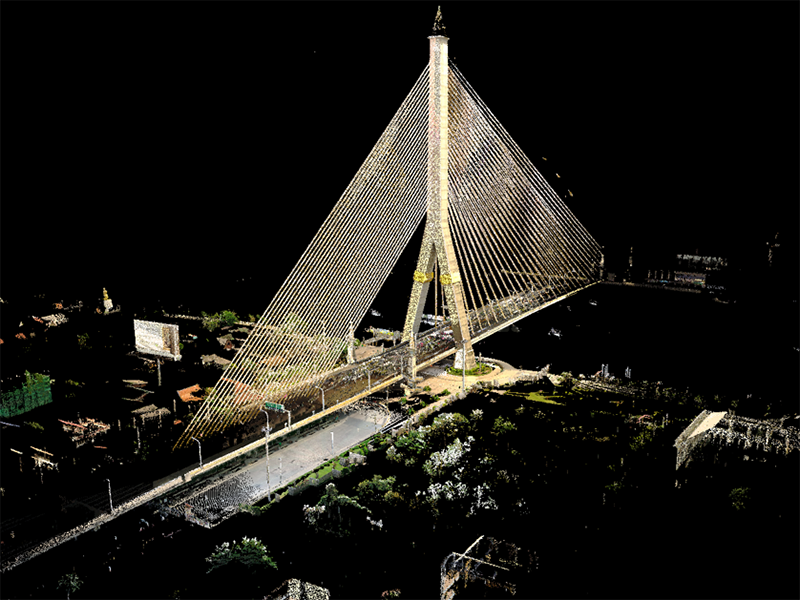

KUMONOS Co., Ltd.

Osaka Prefecture

2-1-15 Semba-higashi,Minoh,Osaka Prefecture 562-0035

Advanced Technologies, AI Robotics, Space Industry

KUMONOS Co., Ltd. Osaka Prefecture https://kumonos.co.jp/global/en/

KUMONOS Co., Ltd. is working to realize a safe, secure and prosperous society with state-of-the-art measuring technology. The company's proprietary “KUMONOS” technology, which can detect cracks with a width of 0.2 millimeters from a distance of 100 meters, is the only one of its kind in the world. The high-precision measurement ability of the KUMONOS technology and the firm's “SHIN KUMONOS” system, which also employs high-resolution photography, enable safe and efficient inspections for large buildings, difficult with conventional methods, as well as external walls and other structures, including even those with hazardous conditions and in dangerous areas. Contactless damage measurement and analysis are possible. The company's 3D measurement technology, employing a 3D laser scanner that can collect one million points of point cloud data per second, has been used for a total of about 3,000 projects in Japan and abroad. Experienced technicians from the company analyze every structure three-dimensionally.

Tour Location

Availability of Company Tours

Contact Information

Spatial Information Business, Business Headquarters

Takatori Corporation

Nara Prefecture

313-1 Shindo-cho, Kashihara, Nara Prefecture, 634-8580

Advanced Technologies, AI Robotics, Space Industry

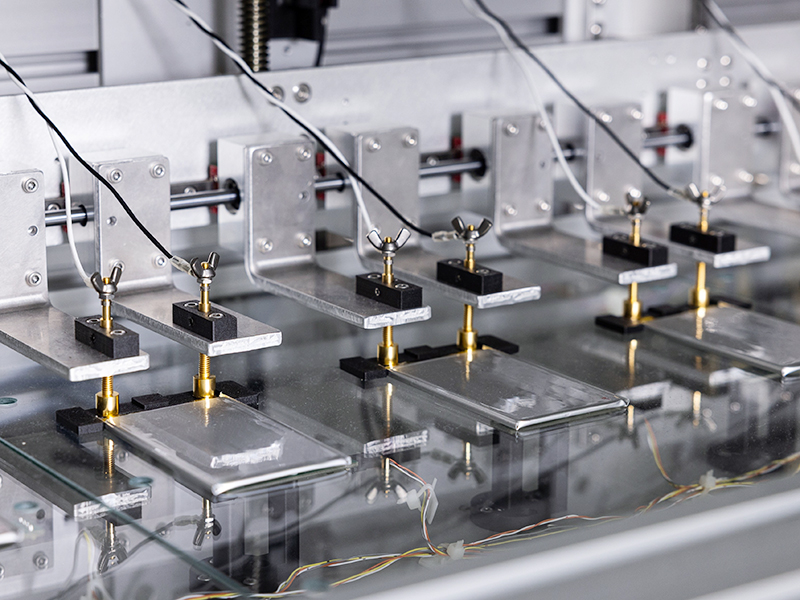

Takatori Corporation Nara Prefecture https://www.takatori-g.co.jp/english/index.html

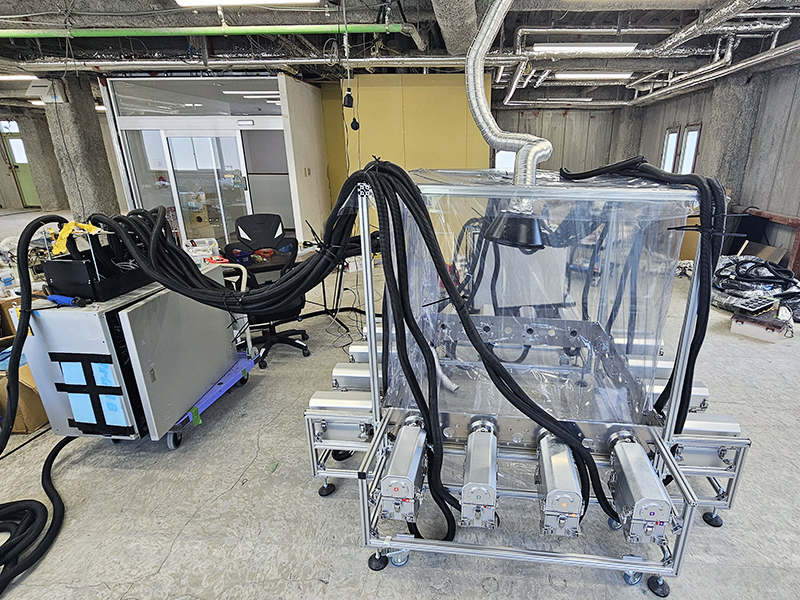

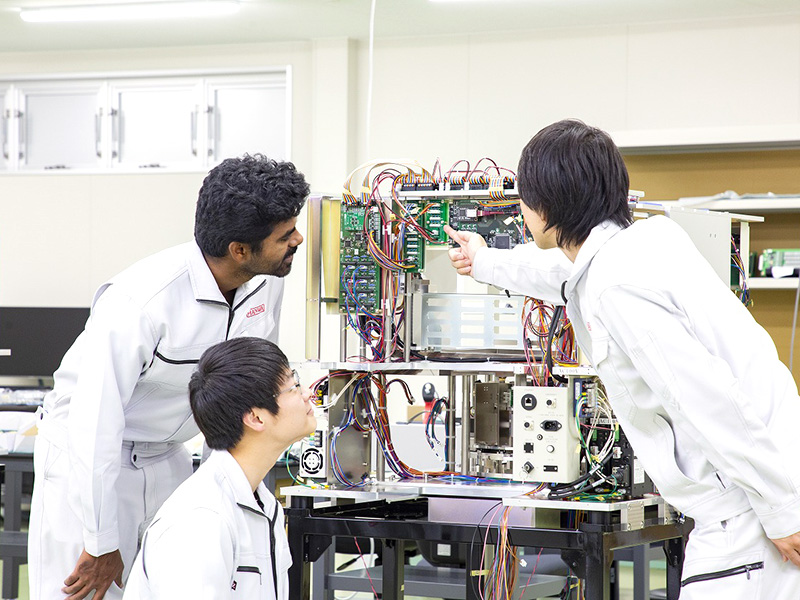

Takatori Corporation is an industrial equipment manufacturer always committed to meeting the new needs of the times, as well as contributing to people's lives and the development of industrial society.

Since its founding in 1950, the company has worked to facilitate the growth of its customers, believing that its corporate value lies in "the production of things that have not been found in the world." This attitude reflects the corporate motto of "Creation and Innovation." The company has taken on challenges on the global stage, always trying to keep ahead of the times, seeking to propose solutions to meet the diversifying needs of customers with its own latest technologies and those developed jointly with others.

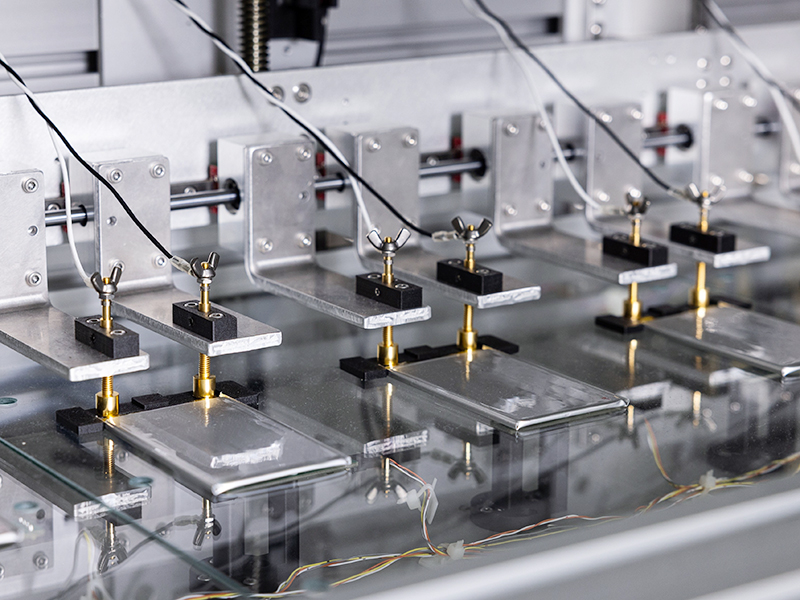

As its core business, the company develops, manufactures and sells cutting machines (multi-wire saw) and grinding machines for extremely hard but brittle materials with labor-saving and streamlining functions, manufacturing equipment for semiconductors and panel displays, and high-efficiency and high-precision cutting machines (automatic cutting machines) for functional fiber materials.

In the medical devices sector, Takatori manufactures and sells ascitic fluid filtration concentration devices and supplies ODM and OEM products. In addition, the company has started developing devices for the practical application of all-solid-state lithium-ion batteries in preparation for a carbon-neutral society.

Tour Location

A 15-minute drive from Yamato-Yagi Station on Kintetsu Railway Co.'s Osaka Line and Kashihara Line

About 50 minutes' drive from Kansai International Airport

Availability of Company Tours

Contact Information

Personnel and General Affairs Department, Administration Headquarters

Chinougijutsu Co., Ltd.

City of Osaka

Dojima Building #414, 2-6-8 Nishi-tenma, Kita Ward,Osaka, Osaka Prefecture 530-0047

Advanced Technologies, AI Robotics, Space Industry

Chinougijutsu Co., Ltd. City of Osaka https://www.chinou.co.jp/en/home/

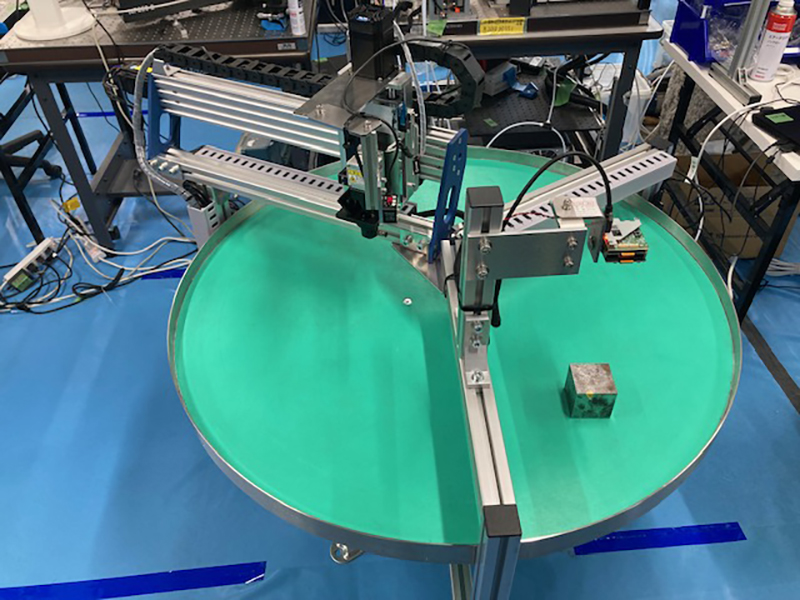

Chinougijutsu Co., Ltd. is working to solve various social challenges by making full use of AI and robot technologies. It is developing robots for a range of purposes, including construction, firefighting,warehouse transportation and plant inspection, as well as automatic driving using generated AI,detection sensors for aging facilities, and AI for recognizing human actions. In particular, the company's strength is its ability to combine AI and robot technology to address dangerous and harsh working conditions and labor shortages at construction sites, fire sites, factories and warehouses, as well as on ships. Top-level universities and companies around the world are paying attention to the company's advanced technological capabilities.

Tour Location

About 15 minutes' drive from Shin-Osaka Station

About 30 minutes' drive from Osaka International Airport (Itami Airport)

Availability of Company Tours

Contact Information

CEO

Nissin Seal Industry Co., Ltd.

Sakai

4-2-11 Mokuzai-dori,Mihara Ward, Sakai,Osaka Prefecture 587-0042

Advanced Technologies, AI Robotics, Space Industry

Nissin Seal Industry Co., Ltd. Sakai https://nissinseal.co.jp/index.html

Manufacturing flexible packages is the main business area of Nissin Seal Industry Co., Ltd..The firm has introduced state-of-the-art printing and pouch-making machines, and provides technology for high-quality printing and a range of manufacturing and processing technologies for pouches. In particular, it has a printing machine capable of employing up to 11 colors for gravure printing. It can also reproduce delicate designs and photographic images. For pouches, the company has an array of equipment and technologies, such as BXP machines, to make special products including spouts and shaped pouches, so it can offer optimal packages that meet a variety of customer needs. Moreover, the company is actively working to reduce environmental burdens by offering products that conform to the green purchasing law as well as items using biomass films and inks,introducing volatile organic compound(VOC) treatment equipment and cutting the amount of waste.

Tour Location

About 1 hour's drive from Shin-Osaka Station

Availability of Company Tours

Contact Information

Personnel Affairs and General Administration Department

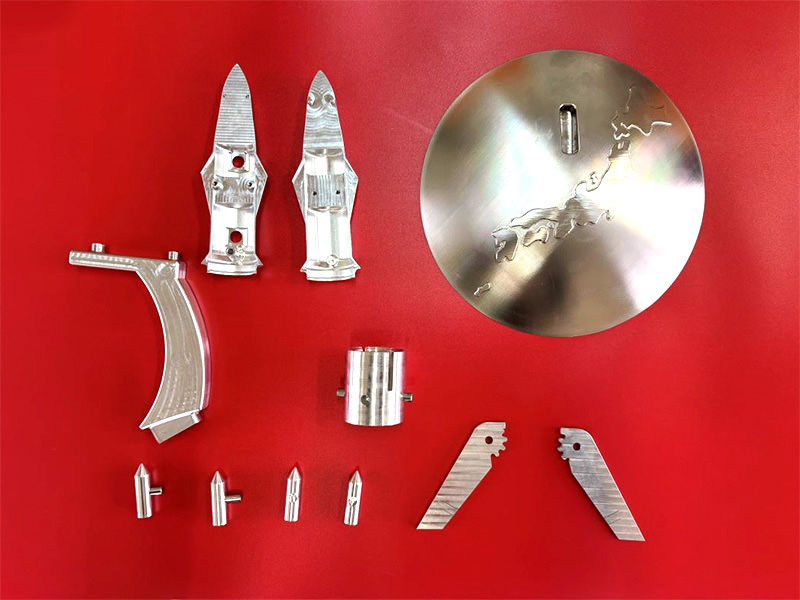

MASUYAMA-MFG Corporation

Tottori Prefecture

43 Nanei-cho, Tottori, Tottori Prefecture, 689-1121

Advanced Technologies, AI Robotics, Space Industry

MASUYAMA-MFG Corporation Tottori Prefecture https://masuyama-mfg.co.jp/

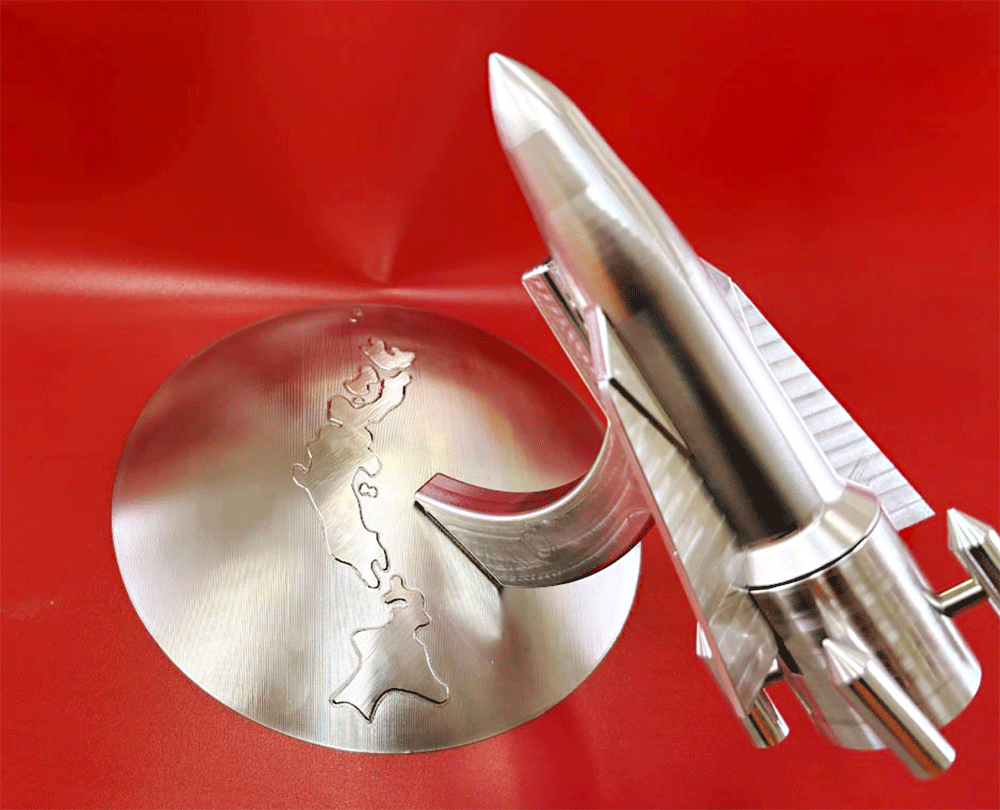

MASUYAMA-MFG Corporation specializes in metal processing, combining high precision with fast processing speeds. The company produces a variety of parts, with a dimensional tolerance of ±10μ and a geometric tolerance of ±20μ. It makes almost all of its parts by scraping from rectangular blocks. Rocket bodies are produced through the scraping of an 8x10x15cm block to a thickness of 2mm. Using the same technology, the company produces casings for CubeSat microsatellites and other space parts.

With 3D processing data utilized as master data, it also conducts all in-house processing by 3D CAM. Manufacturing is carried out on the basis of a simple meeting and 3D data. In addition, MASUYAMA-MFG produces fuel cell-related products, parts for semiconductor-manufacturing equipment, and various industrial machinery parts.

For example, the three-part block pictured nearby was created with "hameai" fitting technology. The shape of Tottori Prefecture pops out to the side by air compression at the push of a rod from above. When the rod is pulled back, the shape disappears, leaving the side surface smooth. The clearance between these parts is 2μ.

The company contributes to society with high-precision manufacturing with the use of aluminum and stainless steel materials, as well as hard-to-cut materials such as Inconel.

Tour Location

About 20 minutes' drive from Tottori Airport

Availability of Company Tours

Contact Information

Representative Director

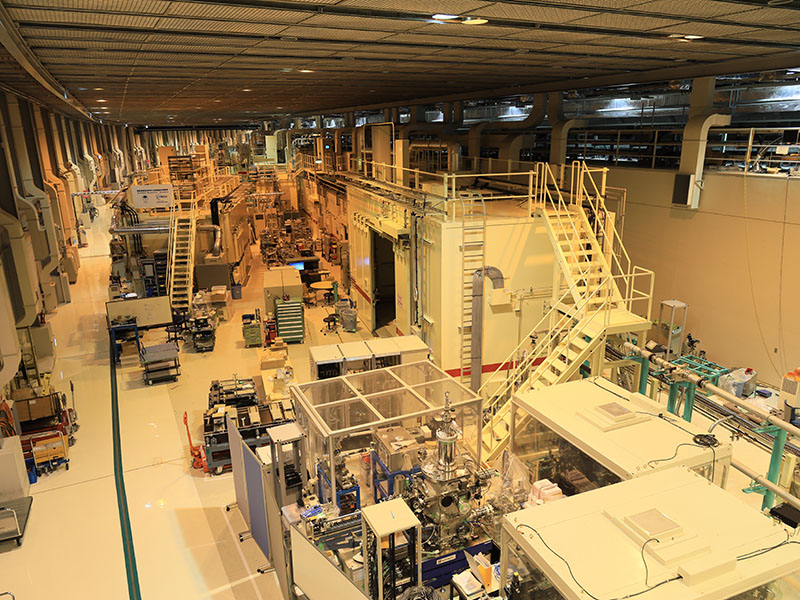

SPring-8 / SACLA

Hyogo Prefecture

1-1-1 Koto, Sayo-cho, Sayo, Hyogo Prefecture, 679-5148

Advanced Technologies, AI Robotics, Space Industry

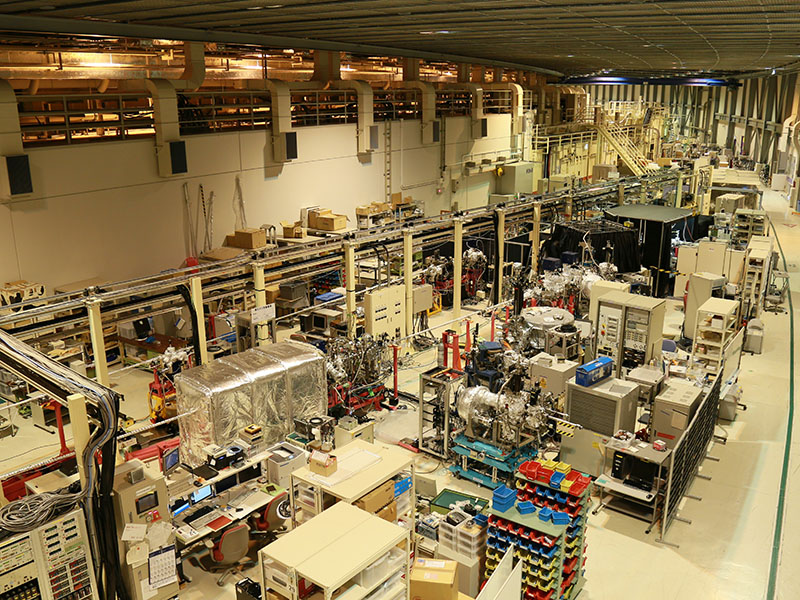

SPring-8 / SACLA Hyogo Prefecture https://new.spring8.or.jp/?lang=en

The large synchrotron radiation facility SPring-8 (Super Photon Ring - 8 GeV) and the X-ray free electron laser facility SACLA (SPring-8 Angstrom Compact Free Electron Laser) are world-class research facilities in Nishiharima, Hyogo Prefecture. Creating powerful synchrotron radiation and X-ray free electron lasers, they are able to analyze the structure and properties of materials in detail at the atomic level. The facilities host cutting-edge research in a variety of fields, including fundamental science, new materials and pharmaceuticals. They also provide opportunities for interdisciplinary exchange with researchers in a wide range of research fields.

Tour Location

About 25 minutes' drive from Shinkansen Aioi Station

Availability of Company Tours

Contact Information

RIKEN SPring-8 Center

Special Note

Tours: About 1 hour and 30 minutes. Visitors are accompanied by a guide.

Smart Laser & Plasma Systems Co.

Tokushima Prefecture

5-4-2 Suketohoncho, Tokushima, Tokushima Prefecture 770-0816

Advanced Technologies, AI Robotics, Space Industry

Smart Laser & Plasma Systems Co. Tokushima Prefecture https://www.slps.jp/english.php

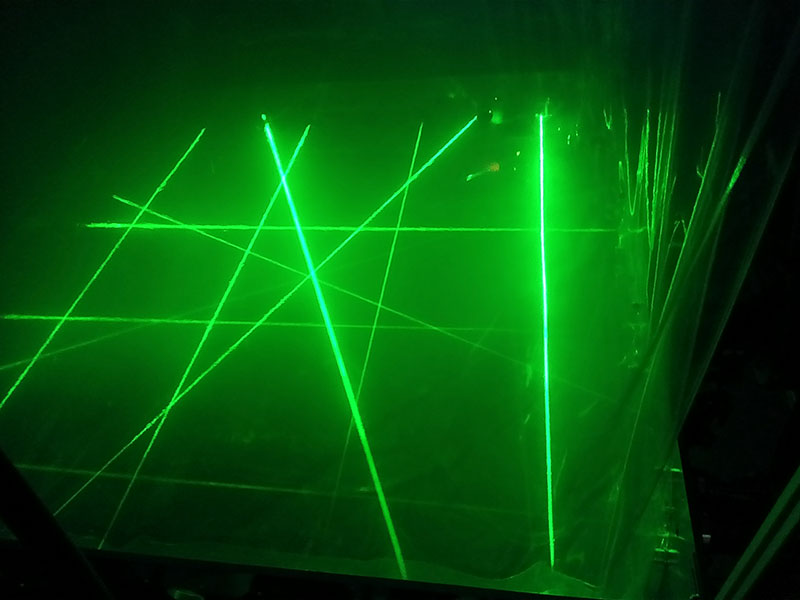

Smart Laser & Plasma Systems was established in 2018 as a startup originating from Tokushima University and the Japan Atomic Energy Agency. The company engages in the design, manufacturing and sales of measurement-related equipment that leverages state-of-the-art laser and plasma research technologies.

The company specializes in process environment measurement systems (CT-TDLAS) and elemental composition analysis systems (LS-DP-LIBS), empowering the visualization and next-generation control of industrial processes. In addition, it is at the forefront of digital transformation with its proprietary Digital Twin technology, which integrates vast amounts of measurement data with artificial intelligence to enable real-time simulations.

Smart Laser & Plasma Systems is gaining recognition for these innovative next-generation technologies, which enable advanced analysis and prediction, and reduce energy consumption and carbon dioxide emissions, while making a significant contribution to global environmental conservation.

Tour Location

Availability of Company Tours

Contact Information

General Affairs Department

Parity Innovations Co. Ltd.

Kyoto Prefecture

Keihanna Plaza Laboratory Wing 6th Floor Hikaridai, Seika-cho, Soraku County, Kyoto Prefecture 619-0237

Advanced Technologies, AI Robotics, Space Industry

Parity Innovations Co. Ltd. Kyoto Prefecture https://www.piq.co.jp/index_e.html

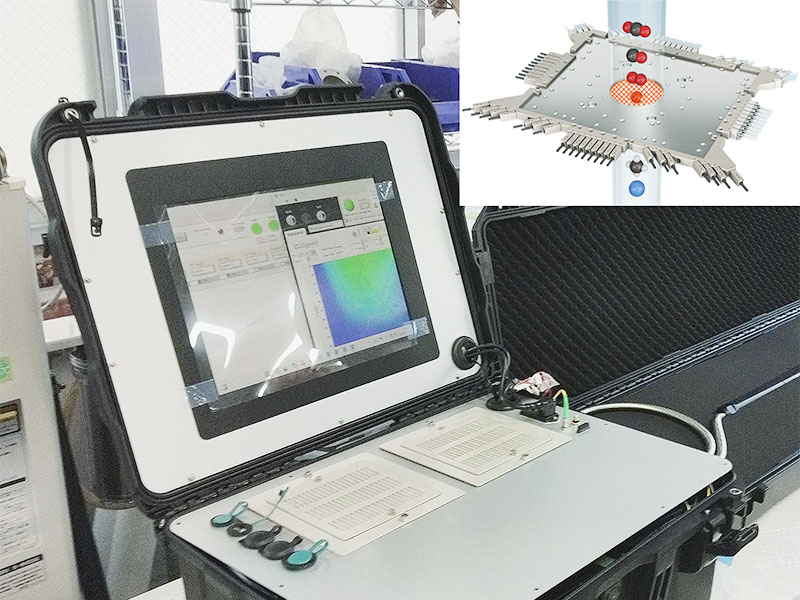

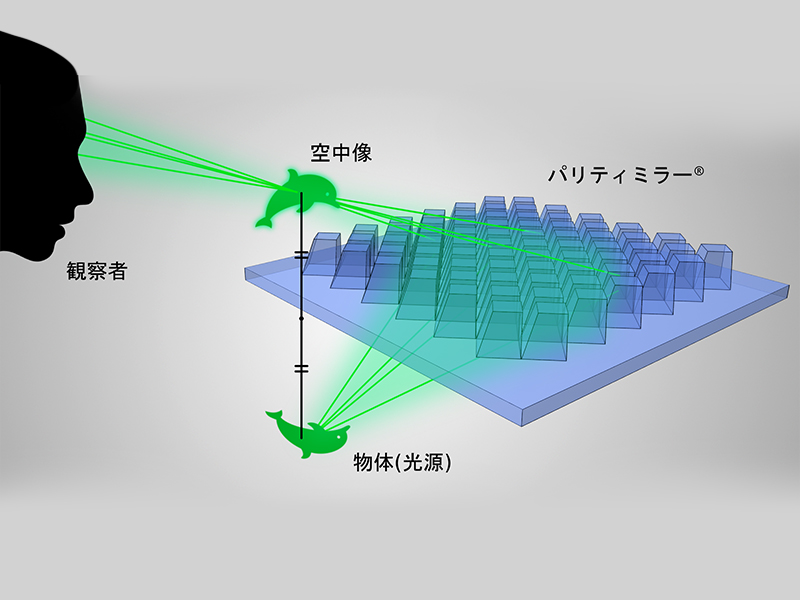

Parity Innovations Co. Ltd. is a pioneering startup that originated at the National Institute of Information and Communications Technology (NICT), and specializes in aerial imaging technologies. The company develops and commercializes innovative products such as its Parity Mirror – a unique device that projects images into midair, creating the illusion of objects floating in space. It also offers aerial touch screens, which allow users to interact with these midair images by touch.

In recognition of its groundbreaking work, Parity Innovations received the award for excellence at the 2023 Monodzukuri Nippon Grand Awards, a prestigious government program celebrating exceptional contributions to "monodzukuri," or artisan manufacturing.

Aerial images produced by Parity Innovations are virtual objects that appear to exist in real space, offering new possibilities for augmented reality experiences. The company also provides contract development services for reality-enhancement systems and interactive solutions featuring virtual characters within aerial images.

Tour Location

About 10 minutes by taxi from Gakken-Nara-Tomigaoka Station of Kintetsu Railway Co.'s Keihanna Line

Availability of Company Tours

Contact Information

Head Office

HANWA ELECTRONIC IND. CO., LTD.

Wakayama Prefecture

689-3 Ogaito, Wakayama, Wakayama Prefecture 649-6272

Advanced Technologies, AI Robotics, Space Industry

HANWA ELECTRONIC IND. CO., LTD. Wakayama Prefecture https://www.hanwa-ei.co.jp/english/index.html

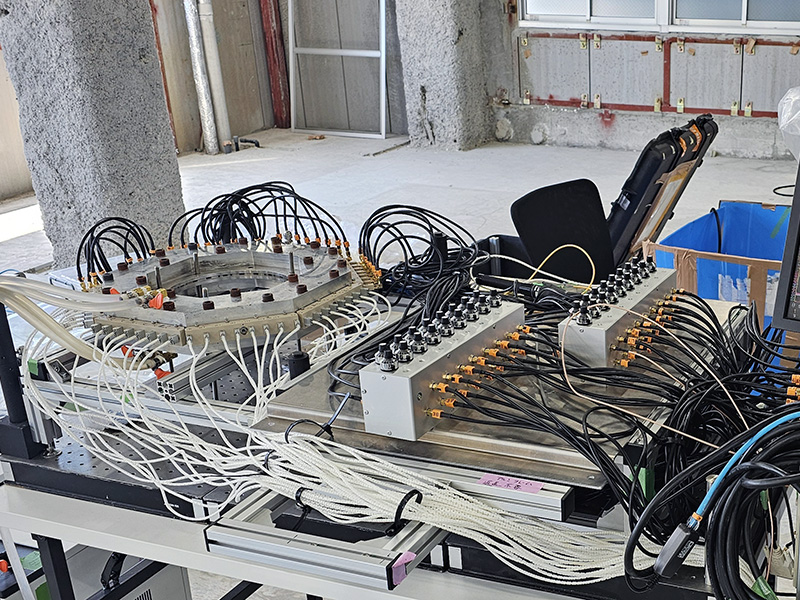

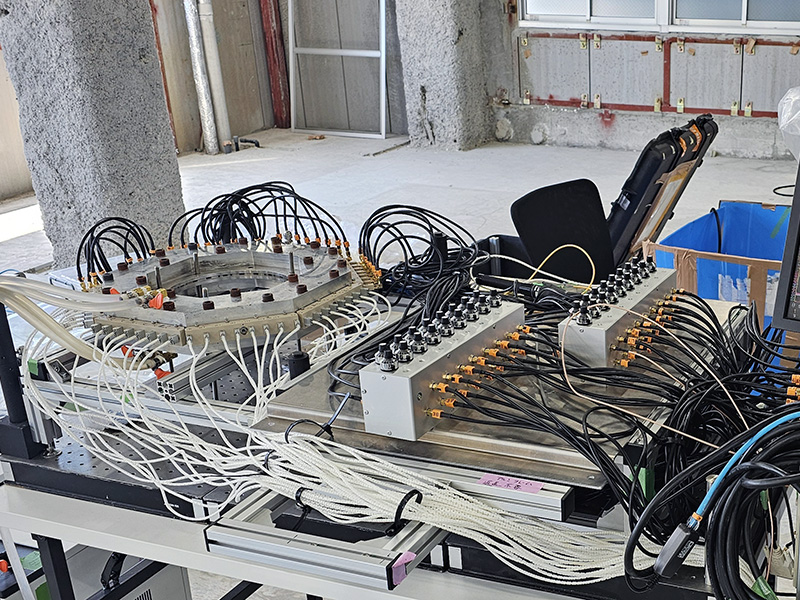

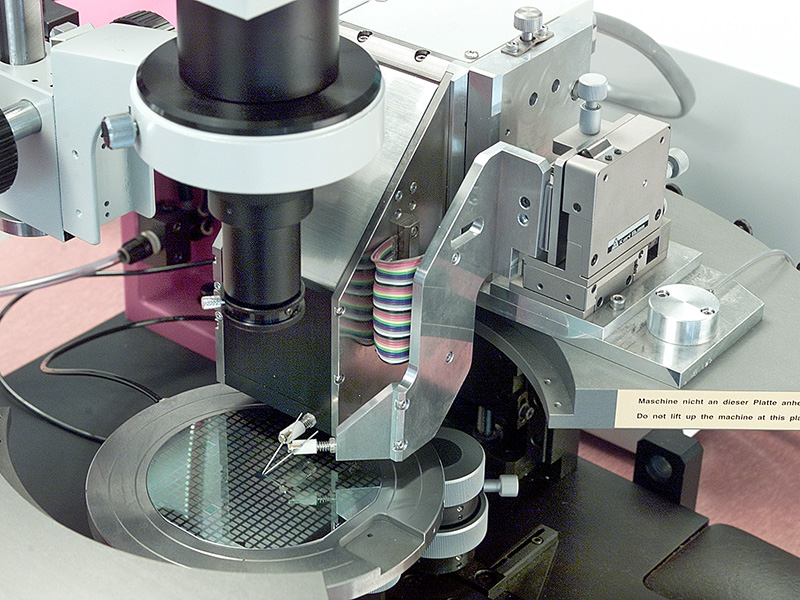

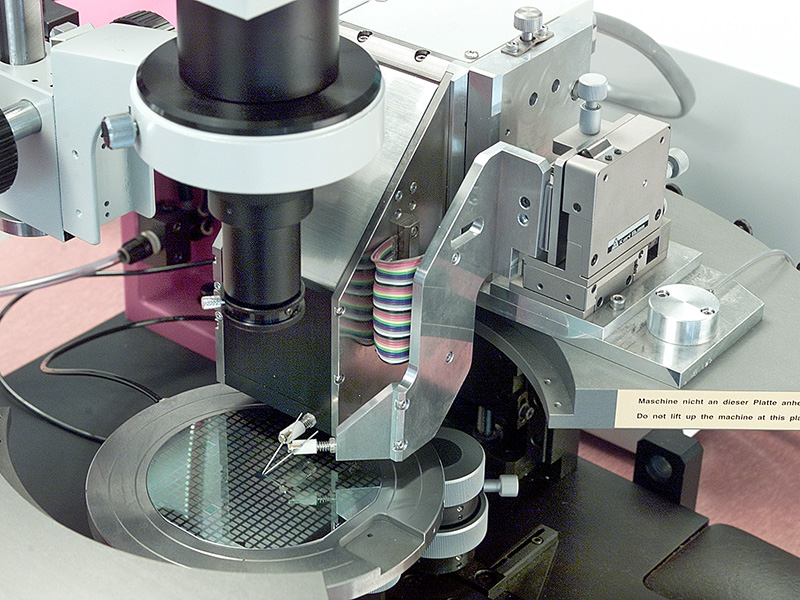

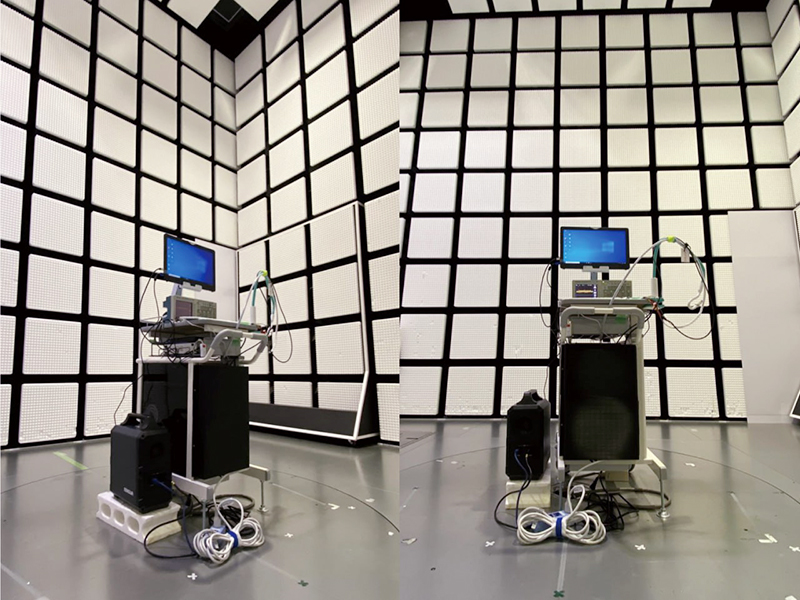

Hanwa Electronic Ind. Co. is a leading developer, manufacturer and supplier of measuring instruments for testing and evaluating semiconductor devices. With a domestic market share exceeding 70% in automatic measurement and analysis equipment utilizing electrostatic discharge (ESD) technology, the company's products are trusted by semiconductor manufacturers, research institutes and universities worldwide.

Hanwa Electronic offers a comprehensive service system that spans every stage of the process – from planning and design to installation and after-sales support – ensuring the consistent fulfillment of diverse customer needs. By integrating marketing insight with technological expertise, Hanwa Electronic delivers high-quality state-of-the-art solutions.

United under the vision "From No. 1 in Japan to No. 1 in the world," Hanwa Electronic employees are dedicated to achieving global excellence.

Tour Location

Availability of Company Tours

Contact Information

General Administration Department

Integral Geometry Science Inc.

Hyogo Prefecture

Room 109, Collaborative HQ block, Kobe University 1-1 Rokkodai-cho, Nada Ward, Kobe, Hyogo Prefecture 657-0013

Advanced Technologies, AI Robotics, Space Industry

Integral Geometry Science Inc. Hyogo Prefecture https://www.igs-group.com/en

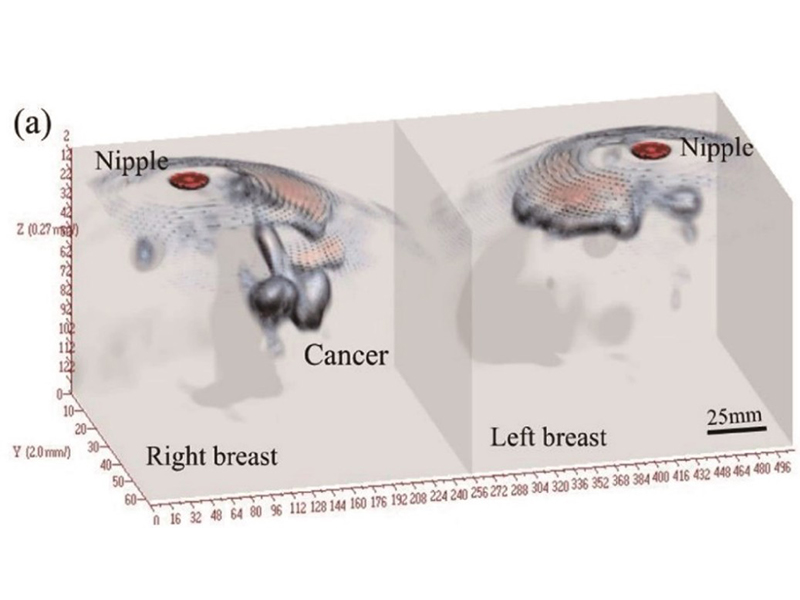

Integral Geometry Science Inc. (IGS) currently conducts R&D and work for commercializing technology aimed at capturing a hidden world that has never been seen. To capture images of the unknown, it is necessary to send waves from the outside world, observe the resulting ripples that repeatedly bounce around before leaking back outside, and then create images.

Known as the inverse problem of wave scattering, this process was an extremely difficult issue in the history of applied mathematics. In 2012, Dr. Kenjiro Kimura succeeded in finding a solution for the first time ever, with his "Inverse Scattering Problem Solution and Imaging Method" recognized across the world and receiving patents.

The same year, IGS was established to utilize the research results in society. At its research base at Kobe University's Incubation Center, the company is engaged in R&D and practical applications for fluoroscopic technology in various fields including medical care, energy and infrastructure.

Tour Location

Availability of Company Tours

Contact Information

Please contact us for information by completing the contact form at https://www.igs-group.com/en/contact

Please contact us for information by completing the contact form at https://www.igs-group.com/en/contact

Please contact us for information by completing the contact form at https://www.igs-group.com/en/contact