Carbon Neutrality

- HOME

- Carbon Neutrality

Pioneering Carbon Neutrality with National-Level Commitment

Addressing climate change is a global priority, with reducing greenhouse gas emissions at the heart of international efforts. While significant investment is required for decarbonization, industries are increasingly viewing carbon neutrality measures as opportunities for new business growth. As a result, decarbonization technologies and innovative business models are gaining traction—both worldwide and in Japan.

Japan has pledged to achieve net-zero greenhouse gas emissions by 2050. In line with this ambitious goal, the government has introduced a "Green Growth Strategy" to drive decarbonization efforts. This initiative supports the development of technologies conducive to carbon neutrality, while providing substantial assistance to companies undertaking decarbonization projects. To encourage related investments, the government is leveraging a full range of policy measures, including the establishment of a 2-trillion-yen fund, tax incentives and regulatory reforms.

In the Kansai region, efforts in research and development (R&D) and practical applications are advancing across a variety of fields, including next-generation storage batteries, solar power generation, hydrogen utilization, carbon capture, and zero-emission mobility such as electric and fuel-cell vehicles. National institutions and local governments actively support these initiatives, positioning carbon neutrality as a business opportunity rather than a financial burden. Reflecting the strong commitment of local industries, Expo 2025 Osaka, Kansai, Japan spotlights carbon neutrality as one of its key themes.

This section highlights companies leading the drive toward carbon neutrality. In addition to visiting the Expo 2025 venue, we invite you to explore these companies at firsthand and witness their cutting-edge technologies in action.

COMPANY LIST Listings:9

Koushi Chemical Industry Co., Ltd.

City of Osaka

1-12-20 Higashi-Obase, Higashinari Ward, Osaka,Osaka Prefecture 537-0024

Carbon Neutrality

Koushi Chemical Industry Co., Ltd. City of Osaka https://koushi-chem.co.jp/en/

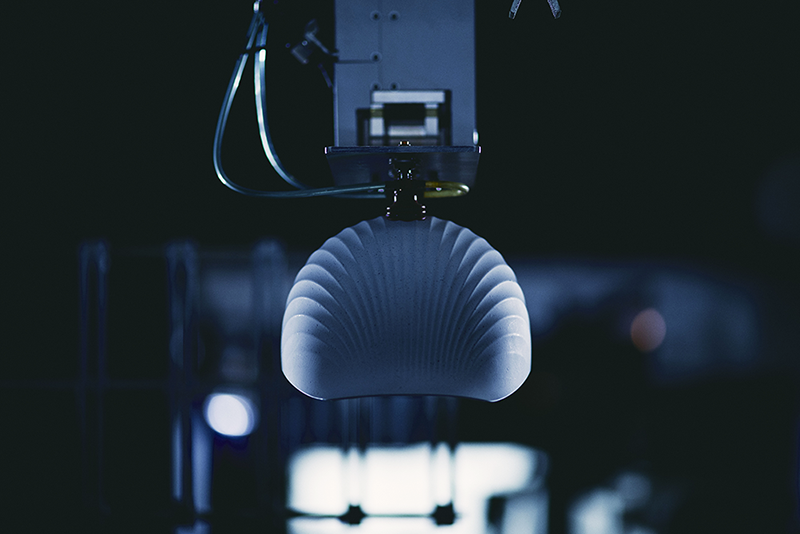

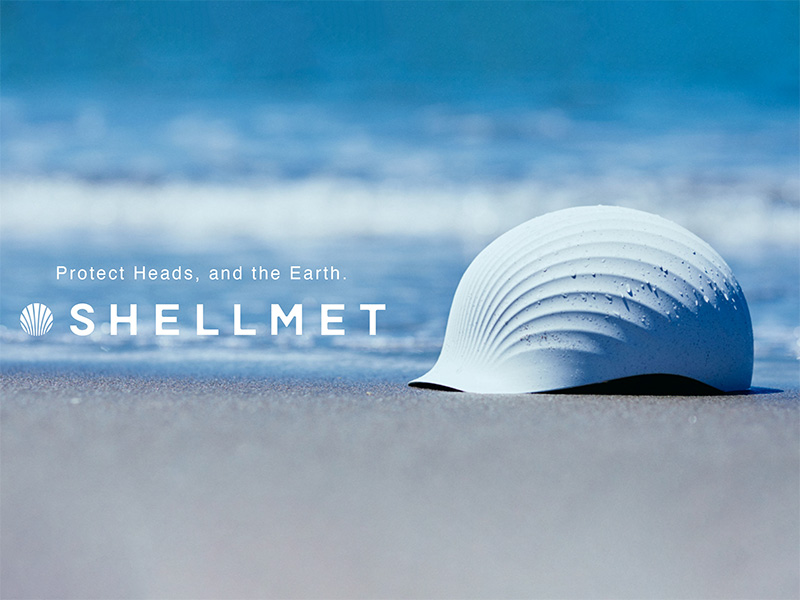

Koushi Chemical Industry is engaged in the design, production and sales of various products, mainly plastics. The company transforms discarded scallop shells into eco-friendly ”SHELLMET” helmets, utilizing ecoplastics derived from the shells. This innovation reduces carbon dioxide (CO₂) emissions by approximately 36% compared with traditional materials. The helmet's design incorporates a unique rib structure inspired by scallop anatomy, resulting in about 33% greater strength than conventional helmets. Damaged SHELLMET helmets are also recyclable, either into new helmets or for use as building materials. By upcycling seashells, which previously contributed to around 40,000 tons of marine waste annually, the company is reducing industrial waste and helping preserve the seaside scenery of Hokkaido and Aomori Prefecture, which are among Japan's leading scallop production areas.

Tour Location

About 40 minutes' drive from Shin-Osaka Station

*Tours are available on certain Saturdays.

Availability of Company Tours

Contact Information

Planning and Development Department

DAIRI FPC CO., LTD.

Tokushima Prefecture

3-77 Tsudakaigan-cho, Tokushima, Tokushima Prefecture, 770-8001

Carbon Neutrality

DAIRI FPC CO., LTD. Tokushima Prefecture https://www.dairinet.com/

DAIRI FPC CO., LTD. is a maker of wood building materials, engaging in forest management as well as the sales and production of framing components.

Based on a philosophy of integrated recycling manufacturing, from upstream to downstream, its AOLA subsidiary makes building materials and household goods painted with indigo dye, a local resource in Tokushima Prefecture, after growing indigo plants and converting indigo into paint.

In its wood operations, Dairi FPC aims for the complete recycling of domestic timber, by eliminating wood waste through biomass power generation.

Tour Location

About 20 minutes' drive from JR Tokushima Station

Availability of Company Tours

Contact Information

Business Management

Special Note

AOLA engages in the recycling-based production of indigo dye goods.

HP:https://aola-bluemission.com/

Email Address:aola.info@gmail.com

Novelgen Co., Ltd.

Shiga Prefecture

Nagahama Bio Incubation Center, Room 15

1281-8 Tamura-cho, Nagahama, Shiga Prefecture 526-0829

Carbon Neutrality

Novelgen Co., Ltd. Shiga Prefecture https://novelgen.jp/

Novelgen Co. is dedicated to research and development (R&D) on innovative solutions utilizing natural microalgae for carbon dioxide (CO₂) absorption and fixation, water purification, and CO₂-based protein production.

Its business model involves licensing proprietary technology to partner companies, enabling its large-scale implementation in society, and receiving license fees. In addition, the company provides comprehensive support to customers that adopt its technology, including microalgae cultivation maintenance, algae supply, and consulting services to address specific challenges.

Its technology maximizes the potential of microalgae to create sustainable solutions.

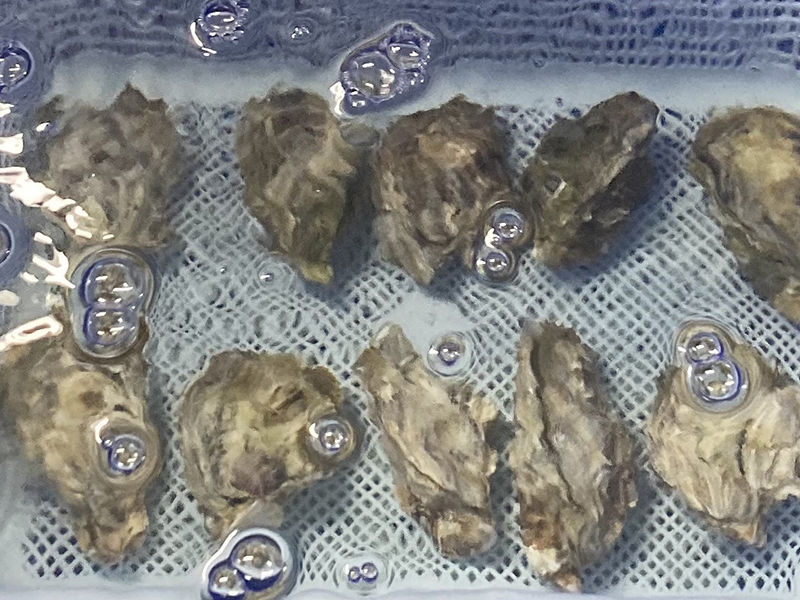

Microalgae grow and multiply through photosynthesis, absorbing CO₂ dissolved in water as a carbon source. Cultivating microalgae can therefore capture CO₂ and purify water simultaneously. Moreover, microalgae serve as a natural feed in aquaculture, facilitating sustainable protein production.

The company has the expertise and capability to customize its solutions for different water sources, ensuring they meet the specific needs of partner companies. Introducing its technology primarily to factories, power plants and water treatment facilities will help achieve both carbon neutrality and water neutrality, contributing to the resolution of global challenges such as climate change, water scarcity and protein security.

Tour Location

1281-8 Tamura-cho, Nagahama, Shiga Prefecture 526-0829

Availability of Company Tours

Contact Information

Photo-on-Demand Chemical Co., Ltd.

Kobe

Kobe University, Graduate School of Science A228 1-1 Rokkodai-cho, Nada Ward, Kobe, Hyogo Prefecture 657-8501

Carbon Neutrality

Photo-on-Demand Chemical Co., Ltd. Kobe https://photo-od-chem.com/

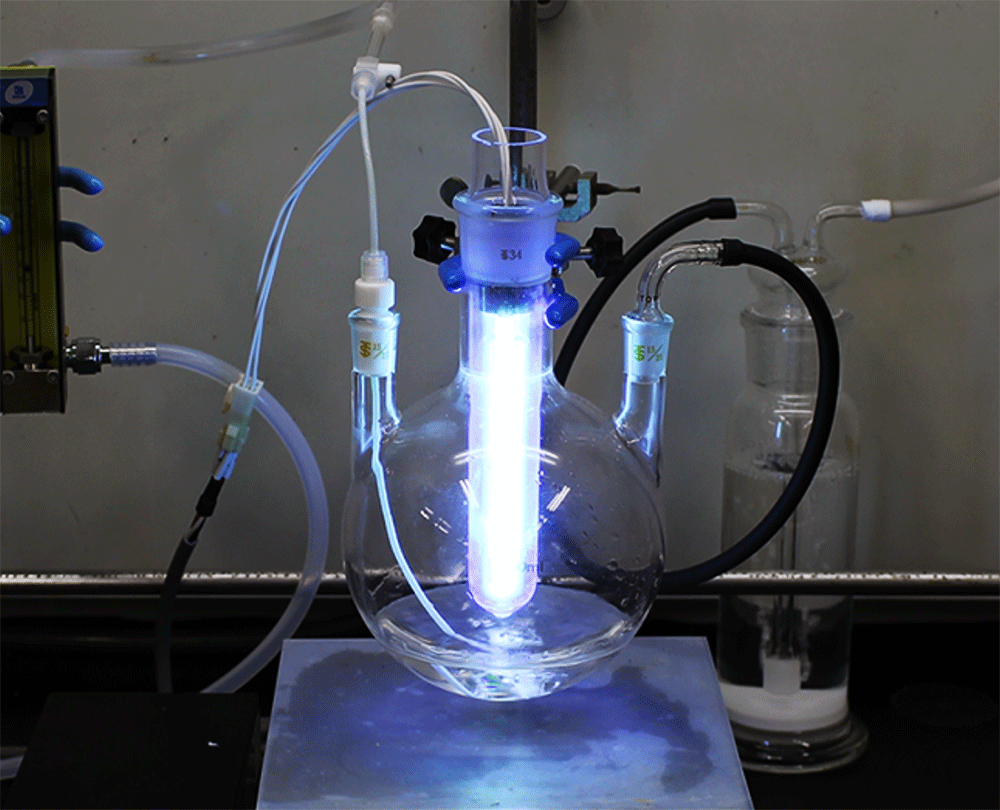

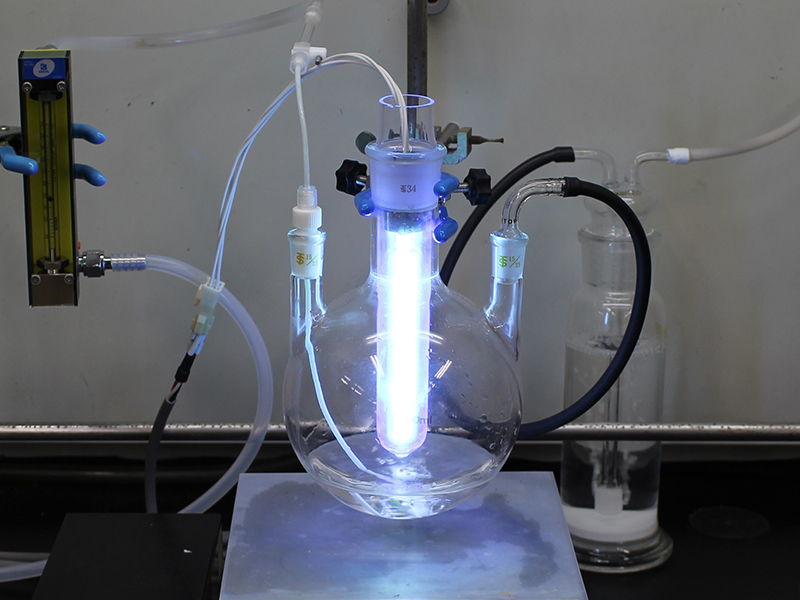

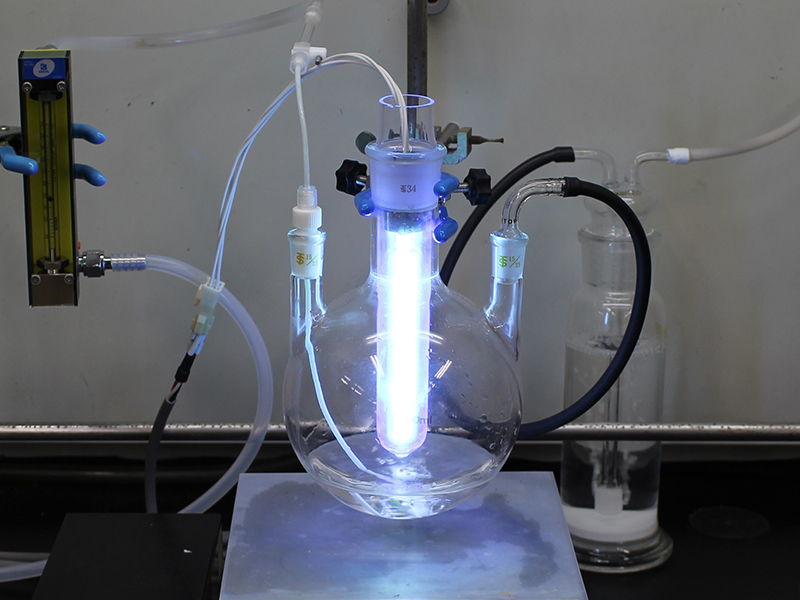

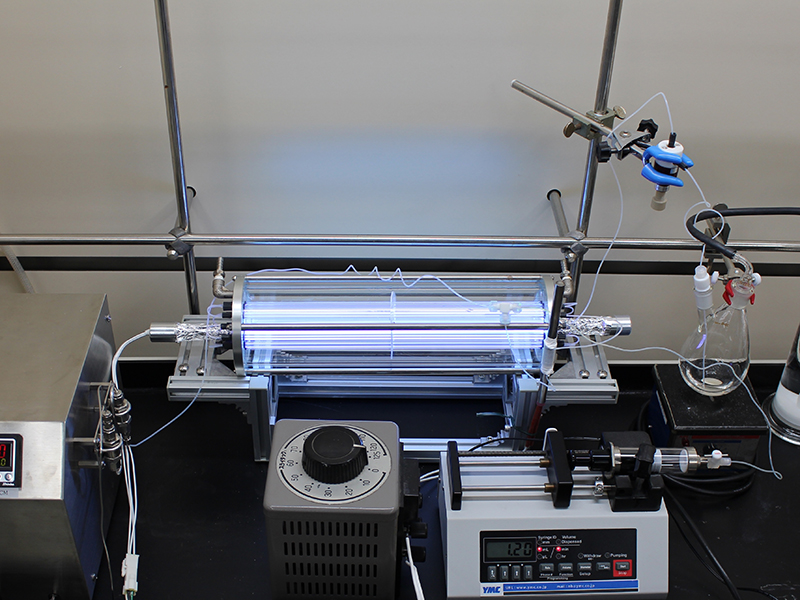

Photo-on-Demand Chemical Co., Ltd. is a startup that uses methane-- a main component of biogas generated from sewage,livestock manure and garbage--chlorine generated from the electrolysis of seawater,and oxygen contained in the air as raw materials to produce active pharmaceutical ingredients and intermediates using light.Methane is a greenhouse gas with a global warming potential approximately 25 times greater than that of carbon dioxide, and there is a strong need to reduce emissions of it into the atmosphere. The company manufactures and sells high-value-added chemical products using biogas as a raw material, employing its patented manufacturing method, which is safe, inexpensive, simple, and environmentally friendly. The startup aims to contribute to U.N. sustainable development goals by forming a hub for manufacturing using light under an industry-government-academic-finance consortium.

Tour Location

About 40 minutes' drive from Osaka International Airport (Itami Airport)

Availability of Company Tours

Contact Information

Business Dept

Special Note

*The requirements for the company tour include that participants must be from countries and regions on Japan's “white” list of trading partners with preferential status and that they sign a nondisclosure agreement.

Renaissance Energy Research Corporation

City of Kyoto

105 Jibu-cho,Fushimi-ku, Kyoto-shi, Kyoto Prefecture Advanced Chemical Technology Center in Kyoto #102 612-8374

Carbon Neutrality

Renaissance Energy Research Corporation City of Kyoto https://www.r-energy.com/

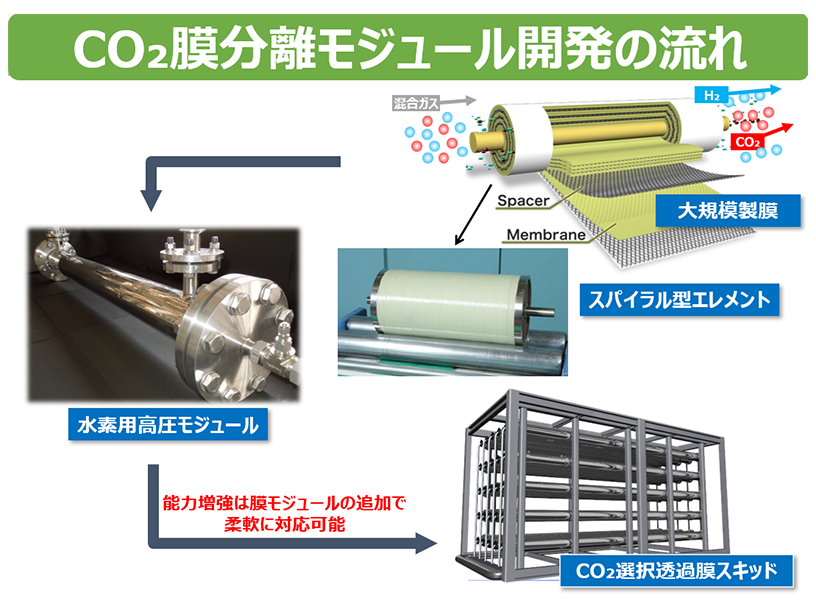

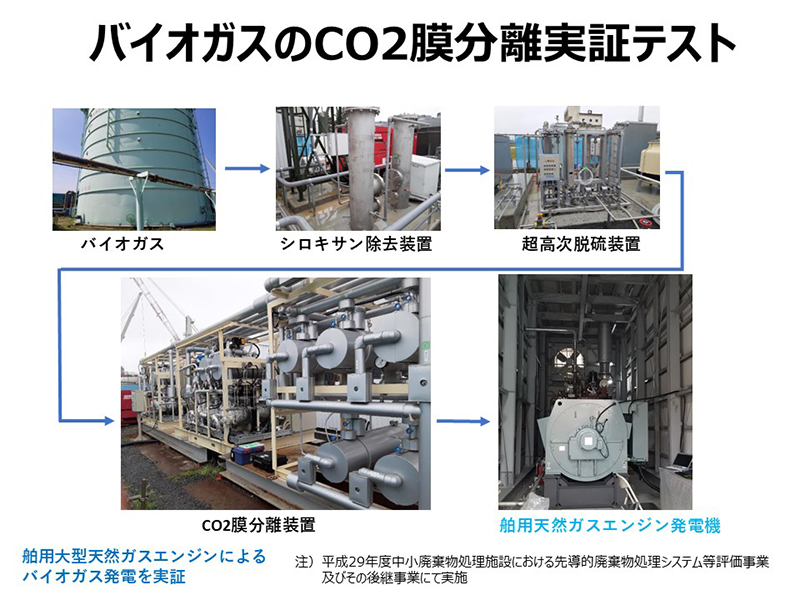

Renaissance Energy Research was established with the aim of developing businesses across a wide range of areas using catalyst-related technologies developed by founder Osamu Okada during his previous job, at Osaka Gas Co. Having obtaining rights from the earlier employer to manufacture, sell, and license related patents, Renaissance Energy Research sells catalysts for hydrogen production to chemical and oil companies in Japan and abroad. It also promotes applications of a carbon-dioxide selective permeable membrane developed in cooperation with Kobe University for carbon-dioxide separation and recovery. The membrane system developed by the company makes it possible to improve the efficiency, reduce the size and lower the cost of hydrogen stations. The company aims to promote application of the system to various fields,such as power genaration exhaust gas,biogas and DAC(Direct Air Capture).Meanwhile, it has successfully developed a carbon-dioxide methanation catalyst with excellent low-temperature activaity. It plans to advance the development of recycling technology for carbon dioxide recovered by membrane separation to contribute to the realization of a decarbonized society.

Tour Location

40 minutes' drive from Osaka International Airport (Itami Airport)

Availability of Company Tours

Contact Information

General Manager,Kyoto Development Center, Technical Headquarters

WEF Institute of Technology Inc.

Shiga Prefecture

1-19-15 Do, Otsu, Shiga Prefecture 520-2116

Carbon Neutrality

WEF Institute of Technology Inc. Shiga Prefecture https://aoyama-wefit.com/en/index.html

WEF Institute of Technology manufactures and sells advanced equipment featuring the world's only technology capable of generating large volumes of active oxygen in the atmosphere at low cost. Its flagship Polaris series enables complete oxidative decomposition of various organic substances without the need for incineration. The W-Gaia system transforms high-concentration, hard-to-process wastewater into readily biodegradable forms at low cost. Its α-Gaia technology instantaneously breaks down the cell walls of animal and plant residues, dramatically reducing the time required for converting high-moisture materials, including excess sludge and aquatic weeds, into valuable resources such as compost or fuel.

The active oxygen treatment devices are registered with the Sustainable Technology Promotion Platform of the United Nations Industrial Development Organization (UNIDO). These innovative solutions are currently deployed in the Gulf of Mexico, the Caribbean Sea and Thailand to effectively address large-scale water hyacinth and Sargassum proliferation.

Tour Location

Availability of Company Tours

Contact Information

Representative Director

JAPAN NOVOPAN INDUSTRIAL CO., LTD.

Sakai

4 Chikkominami-machi, Sakai Ward, Sakai, Osaka Prefecture 590-0987

Carbon Neutrality

JAPAN NOVOPAN INDUSTRIAL CO., LTD. Sakai https://www.novopan.co.jp/en/

Japan Novopan Industrial Co. is a leading manufacturer of particle boards – marketed under the "Novopan" brand – a key material in construction. The boards are made entirely from recycled waste wood and unused wood chips. Inspired by the Japanese concept of "mottainai," which expresses regret over waste coupled with a desire to conserve, the company annually recycles approximately 230,000 tons of woodchips and waste wood generated from urban sources, transforming them into Novopan particle boards. Committed to the advanced utilization of wood resources, Japan Novopan has established itself as Japan's largest recycler of waste wood for board manufacturing.

By recycling wood waste into Novopan, the company eliminates the need for incineration and reduces carbon dioxide (CO₂) emissions by slightly more than 370,000 tons per year. Even after accounting for the CO₂ emissions generated during the manufacturing process, Japan Novopan still achieves a net reduction of more than 280,000 tons of CO₂ annually.

The head office plant in Sakai, which boasts Japan's largest production capacity, is equipped with large-scale power-generation facilities that utilize woodchips as fuel. The plant achieves self-sufficiency by integrating material recycling (for board production) with thermal recycling (for power generation and waste heat utilization). This system maximizes CO₂ reduction. Furthermore, by introducing innovative technologies and promoting the expanded use of particle boards as building materials, the company has earned such strong customer trust that Novopan is now synonymous with construction-grade particle boards.

Japan Novopan strives to deliver products that meet market demands for environmental responsibility, safety and health. Key initiatives include promoting the use of alternative materials to lauan plywood sourced from tropical rainforests, and developing STP load-bearing structural wall materials that offer superior resistance against earthquakes and typhoons. Additionally, all products feature boards with ultra-low formaldehyde emissions, helping to prevent sick-building syndrome and to ensure healthier indoor environments.

Tour Location

Availability of Company Tours

Contact Information

Sales Planning Group / Business Planning Group

Special Note

As a general policy, the company does not offer tours to individuals or organizations affiliated with industry competitors.

Fuji Design CO., LTD.

Hyogo Prefecture

358-25 Manshoji-cho, Ono, Hyogo Prefecture 675-1311

Carbon Neutrality

Fuji Design CO., LTD. Hyogo Prefecture https://fuji-d.jp/en/

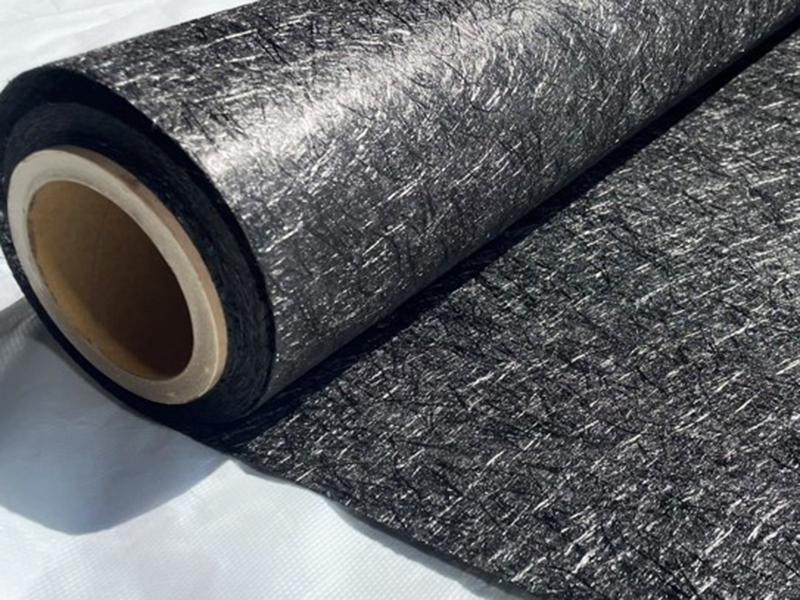

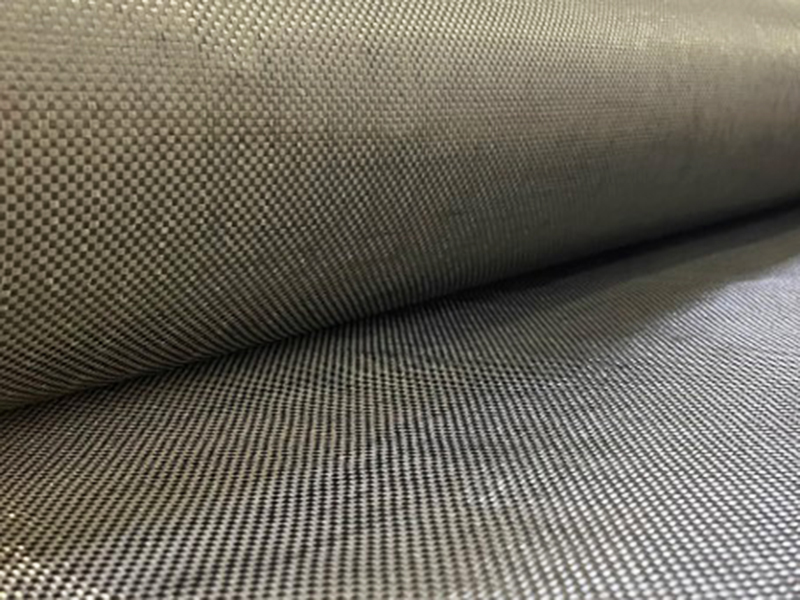

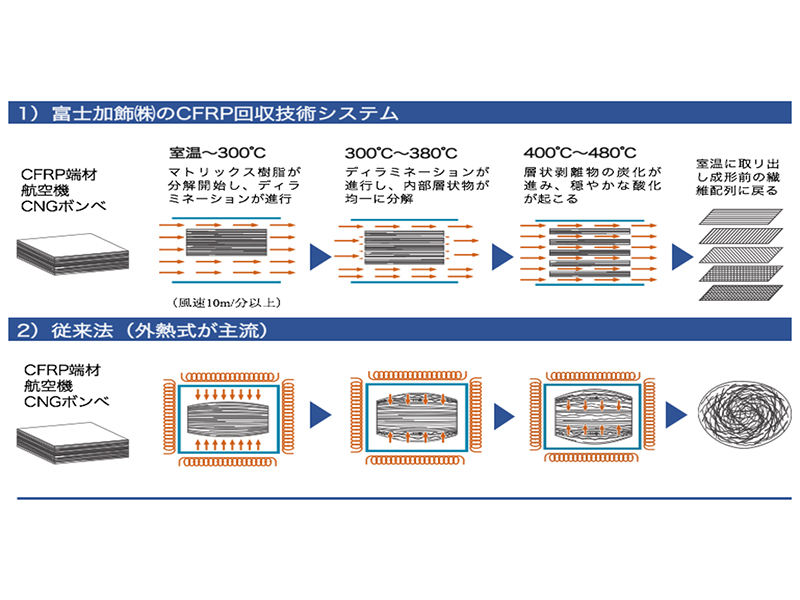

Fuji Design Co. is one of the few companies in Japan to commercialize the recycling of carbon fiber.

With conventional carbon fiber recycling technology, it has been difficult to produce fiber of the same quality as new materials, making commercialization not possible.

The company designed and developed a facility that can recover carbon fiber that is close to new in quality, by processing used carbon fiber reinforced plastics and waste materials with its proprietary precision dry-distillation method.

By combining recycled carbon fiber (rCF) obtained through this technology with Fuji Design's proprietary secondary processing technology, the company developed products that go beyond new carbon fiber in terms of quality.

Seeking wider perspectives and new business opportunities for recycled carbon fiber, Fuji Design is actively publicizing its approach overseas.

Tour Location

408-16 Manshoji-cho, Ono, Hyogo Prefecture 675-1311

Availability of Company Tours

Contact Information

CEO

Special Note

Visits from China and South Korea as well as Japanese companies and universities are not accepted.

As Fuji Design has concluded non-disclosure agreements with many researchers, the company does not accept visits whose purpose is not clear.

In some areas, entry is restricted for the sake of confidentiality.

Yoshikawakuni Plastics Industries, Ltd.

Nara Prefecture

646-2 Kamori, Katsuragi, Nara Prefecture 639-0271

Carbon Neutrality

Yoshikawakuni Plastics Industries, Ltd. Nara Prefecture http://www.yoshikawakuni.co.jp/

Yoshikawakuni Plastics Industries, Ltd., founded in 1932, develops, manufactures, and sells household plastic products under the like-it® brand, utilizing materials such as cellulose nanofibers and other advanced plastics. The brand offers plastic products that feature advanced technologies, with simple designs that enable long use, providing beautiful storage and warm comfort in daily life. Many of its products have received the "G Mark" good design award of the Japanese Ministry of Economy, Trade and Industry. In addition, the company develops composite biomass plastics (Nacel🄬・Nacel light), which use environment-friendly plant-based cellulose, as part of comprehensive efforts to promote resource recycling. It also works for collaborations with companies that utilize cellulose.

Tour Location

Availability of Company Tours

Contact Information

Environmentally Friendly Materials Development Division

Special Note

There are certain conditions that apply to the tour. Please contact us for more information.